Silicon Nitride | Si3N4

MARUWA silicon nitride products have superb characteristics such as high mechanical strength, toughness, and thermal conductivity. As the perfect material for highly reliable products, our silicon nitride substrates are utilized in power electronics modules.

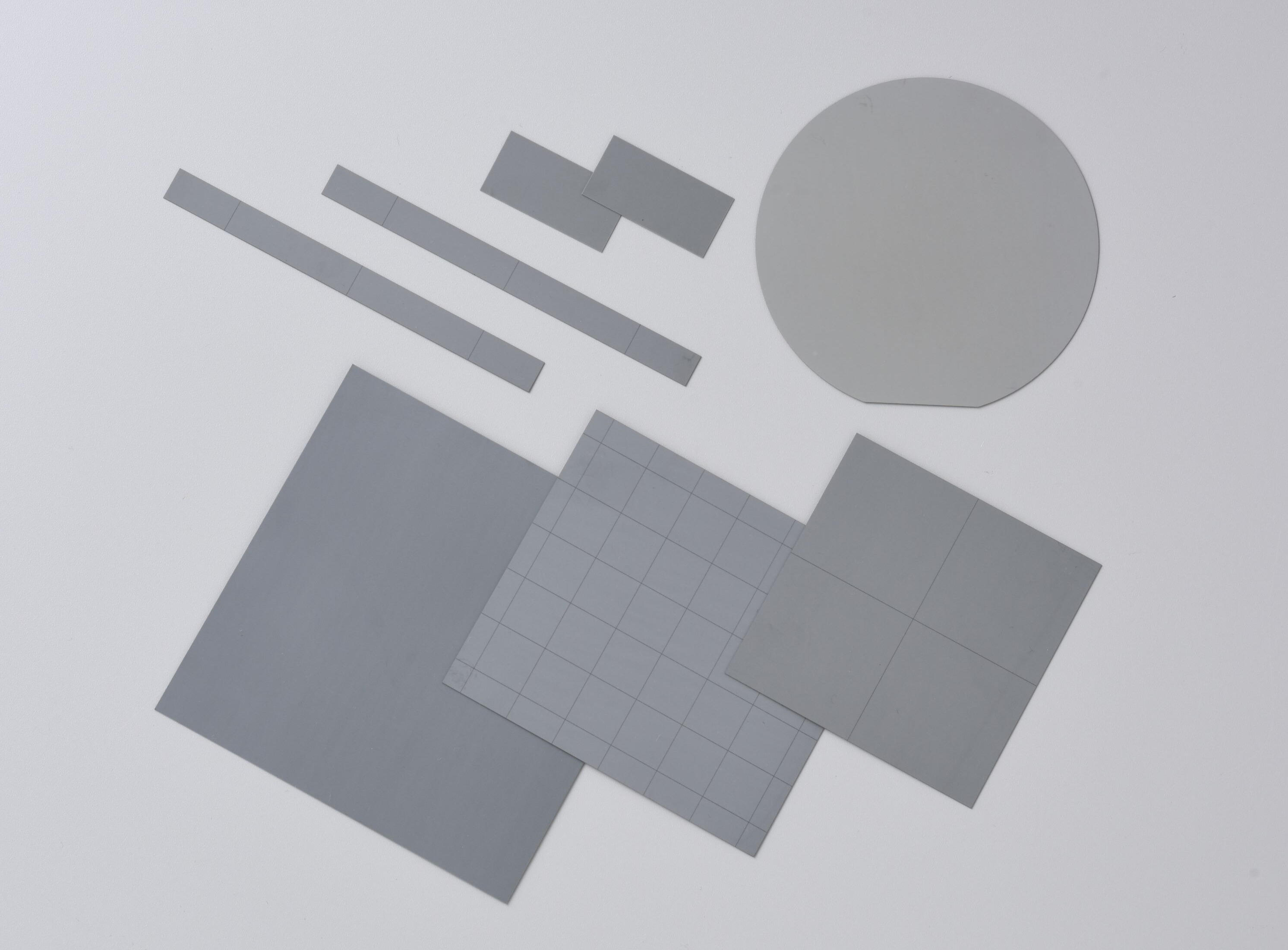

Applications using our silicon nitride (Si3N4) products : Circuit substrate (DBC, DPC, AMB, DBA, thick film, thin film), heat spreader.

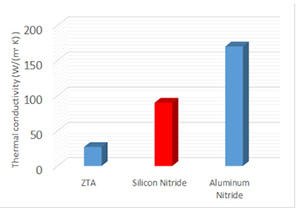

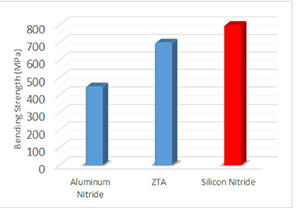

Material Characteristics for Alumina Substrates (Al2O3), Zirconia Toughened Alumina Substrates (Al2O3/ZrO2), Aluminum Nitride (AlN) Substrates,and Silicon Nitride(Si3N4)

| Condition | Unit | Al2O3 | Al2O3/ZrO2 | AlN | Si3N4 | |||

| HA-96-2 | HBS | ZTA | AN-170 | SN-90 | ||||

| Material | - | - | 96% | 96.5% | Al2O3/ZrO2 | AlN | Si3N4 | |

| Color | - | - | White | White | White | Gray | Gray | |

| Bulk density | - | g/㎤ | 3.75 | 3.75 | 4.00 | 3.30 | 3.22 | |

| Surface roughness Ra | - | µm | 0.4 | 0.3 | 0.2 | 0.2 | 0.4 | |

| Reflectivity | 0.3-0.4mmt | % | 70 | 70 | 80 | 35 | - | |

| 0.8-1.0mmt | 80 | 80 | 90 | 25 | - | |||

| Mechanical | Bending strength | 3-point method | MPa | 400 | 500 | 700 | 450 | 800 |

| Modulus of elasticity | - | GPa | 330 | 330 | 310 | 320 | 310 | |

| Vickers hardness | - | GPa | 14 | 14 | 15 | 11 | 15 | |

| Fracture toughness | IF method | MPa・√m | 3.0 | - | 3.5 | 3.0 | 6.5 | |

| Thermal | Coefficient of thermal expansion | 40-400°C | 10-6/K | 6.7 | 6.7 | 7.1 | 4.6 | 2.6 |

| 40-800°C | 7.8 | 7.8 | 8.0 | 5.2 | 3.1 | |||

| Thermal conductivity | 25°C | W/(m・K) | 24 | 24 | 27 | 180 | 85 | |

| 300°C | 12 | 12 | 16 | 120 | - | |||

| Specific heat | 25°C | J/(㎏・K) | 750 | 750 | 720 | 720 | 680 | |

| Electrical | Dielectric constant | 1MHz | - | 9.8 | 9.8 | 10.2 | 8.5 | 7.8 |

| Dielectric loss factor | 1MHz | 10-3 | 0.2 | 0.2 | 0.2 | 0.3 | 0.4 | |

| Volume resistivity | 25°C | Ω・㎝ | >1014 | >1014 | >1014 | >1014 | >1014 | |

| Breakdown strength | DC | ㎸/㎜ | >15 | >15 | >15 | >15 | >15 | |

Characteristic Values

List of Products

Circuit Substrate, Heatsink, Heat Spreader