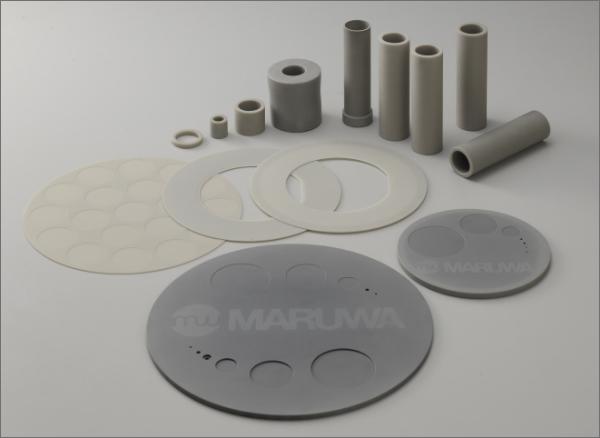

Aluminum Nitride (AlN) Components

Features

With high thermal conductivity, high wear and corrosion resistance, Aluminum Nitride (AlN) is the most ideal material for the semiconductor and medical industries. Typical applications include: heaters, electrostatic chucks, susceptors, clamp rings, cover plates and MRI equipment. Based on a depth of material engineering and development, MARUWA offers a wide range of technical capabilities and dependable mass-production capacity to meet customer’s requirements in the most advanced fields of semiconductor and medical applications.

-

High thermal conductivity as high as metallic aluminum,7 times higher than aluminum oxide (Al2O3)

-

Similar coefficient of thermal expansion to that of silicon (Si)

-

High electric insulation

-

Highly resistant to plasma under fluorine-based gas atmosphere

-

Highly dense and fine-grained structure

-

A variety of materials suitable for different purposes(High thermal conductivity type/High purity type)

-

Sizes suitable for semiconductor manufacturing equipment

Applications

Semiconductor manufacturing equipment (heaters, electrostatic chucks, susceptors, clamps rings, cover plates) and medical equipment

Material properties

| Item | Material | AlN | |||

| HAN-170 | HAN-90 | ||||

| Density | g/㎤ | 3.3 | 3.2 | ||

| Mechanical Characteristic | Flexual Strength | MPa | >350 | >320 | |

| Young's Modulus | GPa | 320 | 320 | ||

| Thermal Characteristic | Specific Heat at RT | J/(㎏・K) | 740 | 730 | |

| Thermal Expansion | ~800°C | 10-6/K | 5 | 5 | |

| Thermal Conductivity | W/(m・K) | 170 | 90 | ||

| Electrical Characteristic | Dielectric Constant | 1MHz | - | 9 | 9 |

| Dielectric Loss | 1MHz | 10-4 | 5 | 4 | |

| Volume Resistivity | 25°C | Ω・㎝ | >1014 | >1012 | |

| Dielectric Breakdown Voltage | ㎸/㎜ | >15 | >15 | ||

| Application | Heater,Heatsink | Susceptor,Ring | |||

Standard size

φ180~380mm × 1~10mmt (φ550 will be available soon)

※Custom sizes are also available.