Aluminum Nitride | AlN

Our Aluminum Nitride (AlN) materials have high thermal conductivity, high electric insulation and have a coefficient of thermal expansion similar to that of silicon (Si). It is used as a substrate for power module and LED.

Material Characteristics for Alumina Substrates (Al2O3), Zirconia Toughened Alumina Substrates (Al2O3/ZrO2), Aluminum Nitride (AlN) Substrates, and Silicon Nitride(Si3N4)

| Condition | Unit | Al2O3 | Al2O3/ZrO2 | AlN | Si3N4 | |||||

| HA-96-2 | HBS | ZTA | AN-170 | AN-200 | AN-230 | SN-90 | ||||

| Material | - | - | 96% | 96.5% | Al2O3/ZrO2 | AlN | AlN | AlN | Si3N4 | |

| Color | - | - | White | White | White | Gray | Gray | Beige | Gray | |

| Bulk density | - | g/㎤ | 3.75 | 3.75 | 4.00 | 3.30 | 3.30 | 3.30 | 3.22 | |

| Surface roughness Ra | - | µm | 0.4 | 0.3 | 0.2 | 0.2 | 0.3 | 0.3 | 0.4 | |

| Reflectivity | 0.3-0.4mmt | % | 70 | 70 | 80 | 35 | - | - | - | |

| 0.8-1.0mmt | 80 | 80 | 90 | 25 | - | - | - | |||

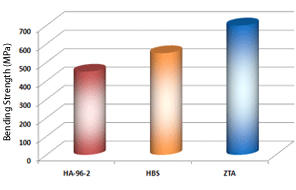

| Mechanical | Bending strength | 3-point method | MPa | 400 | 500 | 700 | 450 | 400 | 350 | 800 |

| Modulus of elasticity | - | GPa | 330 | 330 | 310 | 320 | - | - | 310 | |

| Vickers hardness | - | GPa | 14 | 14 | 15 | 11 | 11 | 11 | 15 | |

| Fracture toughness | IF method | MPa・√m | 3.0 | - | 3.5 | 3.0 | 2.6 | 2.4 | 6.5 | |

| Thermal | Coefficient of thermal expansion | 40-400°C | 10-6/K | 6.7 | 6.7 | 7.1 | 4.6 | 4.6 | 4.6 | 2.6 |

| 40-800°C | 7.8 | 7.8 | 8.0 | 5.2 | 5.2 | 5.2 | 3.1 | |||

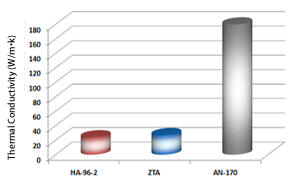

| Thermal conductivity | 25°C | W/(m・K) | 24 | 24 | 27 | 180 | 200 | 230 | 85 | |

| 300°C | 12 | 12 | 16 | 120 | 130 | 145 | - | |||

| Specific heat | 25°C | J/(㎏・K) | 750 | 750 | 720 | 720 | 720 | 720 | 680 | |

| Electrical | Dielectric constant | 1MHz | - | 9.8 | 9.8 | 10.2 | 8.5 | 8.5 | 8.5 | 7.8 |

| Dielectric loss factor | 1MHz | 10-3 | 0.2 | 0.2 | 0.2 | 0.3 | 0.3 | 0.3 | 0.4 | |

| Volume resistivity | 25°C | Ω・㎝ | >1014 | >1014 | >1014 | >1014 | >1014 | >1013 | >1014 | |

| Breakdown strength | DC | ㎸/㎜ | >15 | >15 | >15 | >15 | >15 | >15 | >15 | |

Characteristic Values

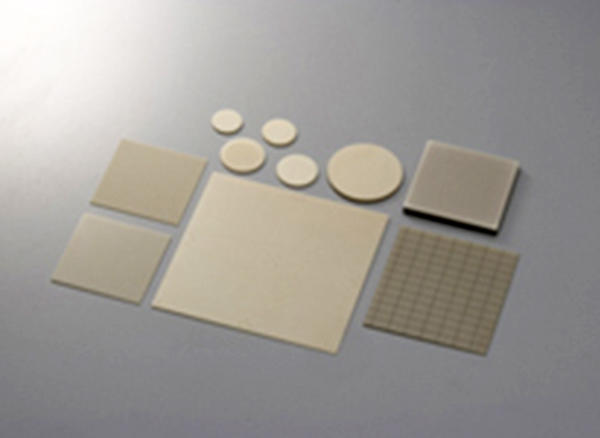

List of Products

Heat dissipation substrate, LED package, Power module, Wafer bonding, Power resistor.

*Various metalized processing is available (Thin film, Thick film, DBC, AMB, DPC, etc.).