Ultra High Purity Fine Ceramic SiC Components (PureBeta)

PureBeta is an ultra-high purity, high density sintered SiC exhibiting superior properties which make it suitable for strict environments, such as semiconductor devices production.

Impurity content (PureBeta)

PureBeta combines high purity of 6N (metal impurities below 1 ppm) with high density (98% of the theoretical density).

| PureBeta | ||

|---|---|---|

| Element | Bulk (ppm) |

Surface

(1010atoms/cm²) |

| B | 0.02 | - |

| Na | <0.01 | - |

| Al | 0.08 | - |

| K | <0.01 | <DL |

| Ti | 0.02 | <DL |

| Cr | 0.02 | <DL |

| Mg | 0.02 | - |

| Fe | 0.05 | 0.02 |

| Co | <0.01 | <DL |

| Ni | <0.01 | <DL |

| Cu | 0.04 | <DL |

| Zn | 0.01 | <DL |

| W | <0.01 | <DL |

Bulk: measured by Glow Discharge Mass Spectroscopy (GD-MS)

Surface: measured by Total Reflection X-ray Fluorescence (TXRF)

DL: Detection Limit

*Analytical values mentioned on the left are representative values only.

Comparison of SiC with other materials

Our proprietory production method allows us to manufacture unique sintered SiC material without using any metal agent.

| Property | SiC (PureBeta) |

Si | C | SiO2 | Al2O3 | AlN | |

|---|---|---|---|---|---|---|---|

| Density | g/cm³ | 3.15 | 2.33 | 1.55 | 2.1 | 3.9 | 3.2 |

| Vickers Hardness | - | 2200 | 1000 | - | 800 | 1900 | 1800 |

| Bending Strength | MPa | 600 | 300 | 120 | 40 | 500 | 300 |

| Modulus of Elasticity | GPa | 390 | 190 | 28 | 66 | 400 | 320 |

| Fracture Toughness | MPa/m0.5 | 4.4 | - | - | - | 3.5 | 3.0 |

| Coefficient of Thermal Expansion | E-6/K | 4.3 | 3.9 | 3.2 | 0.5 | 7.9 | 4.0 |

| Thermal Conductivity | W/m·K | 230 | 160 | 8 | 1 | 38 | 170 |

| Volume Resistivity | Ω·cm | 2E-02 | 2E+04 | 4E-03 | 2E-02 | 1E+14 | 1E+14 |

*Values are representative values only.

PureBeta Specification

| Polytype | Polycrystalline ß-SiC |

|---|---|

| Production Method | Hot Press Sintering |

| Maximum Part Size | ≤Φ480mm x 100mm thickness |

| Corrosion Resistance | Excellent resistance to Hydrofloric Acid, Ion and Plasma |

| Maximum Operating Temperature | In Vacuum: 1400°C, Under Atmospheric Pressure 1700°C |

| Application | High purity semiconductor parts, Heater products |

Various physical properties (PureBeta)

| Property | PureBeta | Measurement Method | |

|---|---|---|---|

| Structure | - | Poly ß-SiC | X-Ray Analysis |

| Density | g/cm³ | 3.15 | Archimedes' Method |

| Vickers Hardness | - | 2200 | Vickers Hardness Tester |

| Bending Strength | MPa | 600 | Three-point Flexural Test |

| Modulus of Elasticity | GPa | 390 | Ultrasonic Pulse-Echo Method |

| Poisson ratio | - | 0.15 | Ultrasonic Pulse-Echo Method |

| Coefficient of Thermal Expansion | /K | 4.3×10-6 | Differential Dilatometer (RT~1000°C) |

| Thermal Conductivity | W/m·K | 230 | Laser Flash Method (RT) |

| Specific heat |

J/g·K

|

0.68 | Differential Scanning Calorimeter (RT) |

| Volume Resistivity | Ω·cm | 0.02 | 4-Points Probe Method (RT) |

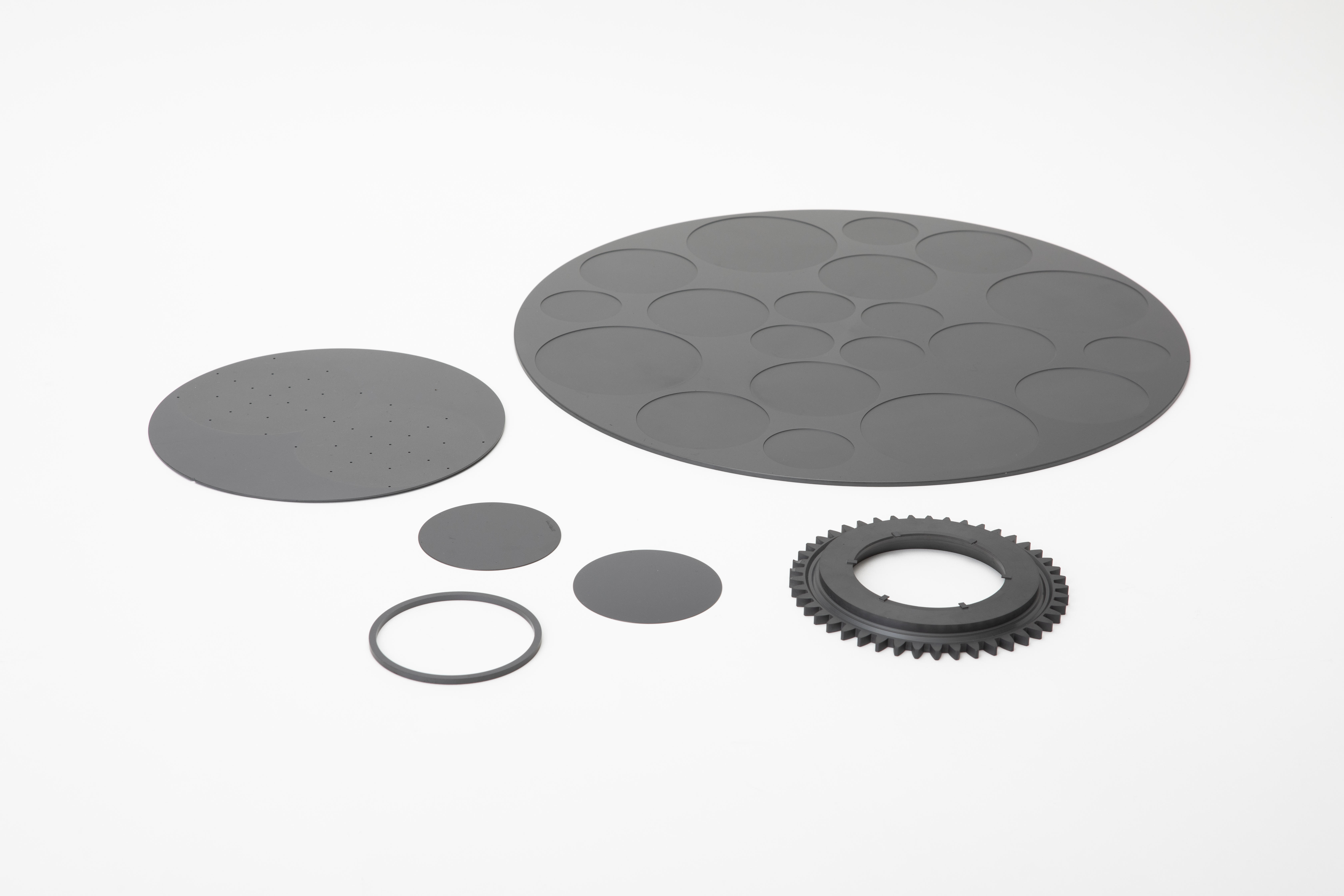

Products

|

Parts for compound semiconductor manufacturing |

Extremely durable and reliable parts produced entirely from ultra-high purity bulk SiC are optimal for GaN-based devices (such as blue and white LEDs) manufacturing. |

|

|---|---|---|

|

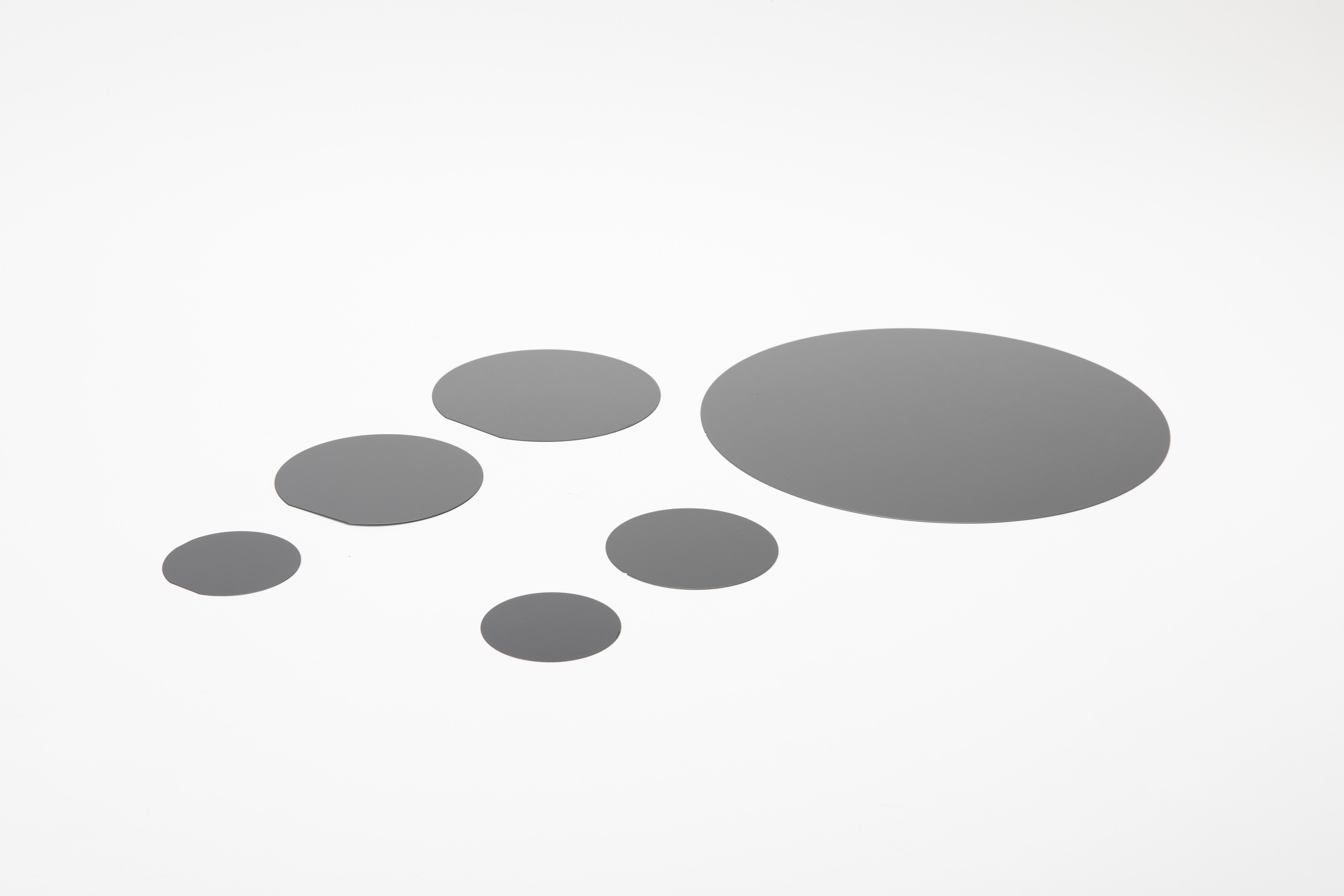

Ultra high purity sintered SiC Dummy Wafers |

High performance dummy wafers with excellent cost performance can be used in various applications. Outstanding shape stability, corrosion resistance, and heat resistance allow for long-term reusability. |

|

|

Heater Elements |

High conductivity allows for a quick raise from room temperature to 1700°C. In addition, its high durability makes it very effective for heating in air or in reactive gas atmosphere. |

|

|

Heater Cover Plates |

Plates protecting the heater stage during process chamber conditioning. |

|

|

Ultra high purity SiC Heater Units |

Ground-breaking wafer heating units made by combination of ultra-high purity SiC material with bonding technology, which covers almost entire temperature range of Si semiconductor device manufacturing (structural material is high-purity quartz). |

|

|

Sputtering Targets |

Can be used for deposition of optical film for fabrication of SiO2 film by laser optical waveguides and for various protective films for mechanical purposes. In addition, its high conductivity is extremely effective in improving efficiency of DC sputtering. |

|

|

Electrodes & Rings |

Excellent plasma resistance, high durability and long lifetime. Furthermore, allowing for particles reduction. |

|

|

Electrode Bonded Heaters |

Our original SiC-SiC bonding technology allows for joining heating elements with electrodes. Temperature of the connection can be controlled by adjusting length and thickness of the electrodes. |

|