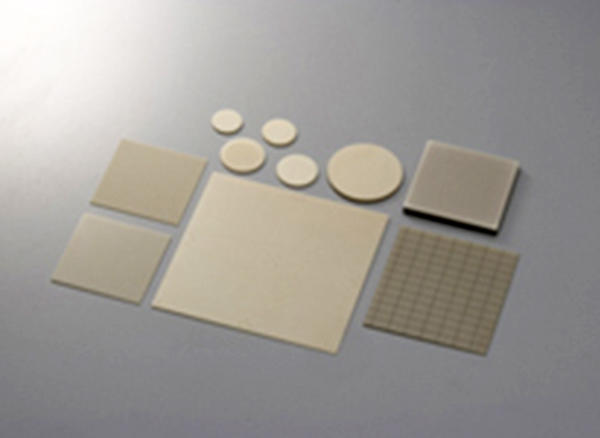

Aluminum Nitride (AlN) Substrates

Features

MARUWA has started to produce Aluminum Nitride (AlN) substrates since 1985 and has developed its performance.

With both extremely high thermal conductivity (170-230W/mK) and insulating properties. MARUWA's AlN substrate can be the best solution in electronics applications where strict conditions are required, such as power modules (MOSFET, IGBT), LED packages for cooling and protecting circuits, packages and modules.

-

High thermal conductivity (170-230W/mK), up to 9.5 times than that of Alumina.

-

Similar coefficient of thermal expansion to that of silicon (Si). This helps to achieve high reliability of Si chip and thermal heat cycling.

-

Higher electric insulation, and Smaller dielectric constant.

-

Higher mechanical strength (450MPa).

-

Superior corrosion resistance against molten metal.

-

Very high purity, no toxicity.

Applications

Heat dissipation substrate, LED package, Power module, Wafer bonding, Power resistor.

*Various metalized processing is available (Thin film, Thick film, DBC, AMB, DPC, etc.).

Characteristic Values

| Condition | Unit | AlN | ||||

| AN-170 | AN-200 | AN-230 | ||||

| Material | - | - | AlN | AlN | AlN | |

| Color | - | - | Gray | Gray | Beige | |

| Bulk density | - | g/㎤ | 3.30 | 3.30 | 3.30 | |

| Surface roughness Ra | - | µm | 0.2 | 0.3 | 0.3 | |

| Reflectivity | 0.3-0.4mmt | % | 35 | - | - | |

| 0.8-1.0mmt | 25 | - | - | |||

| Mechanical | Bending strength | 3-point method | MPa | 450 | 400 | 350 |

| Modulus of elasticity | - | GPa | 320 | - | - | |

| Vickers hardness | - | GPa | 11 | 11 | 11 | |

| Fracture toughness | IF method | MPa・√m | 3.0 | 2.6 | 2.4 | |

| Thermal | Coefficient of thermal expansion | 40-400°C | 10-6/K | 4.6 | 4.6 | 4.6 |

| 40-800°C | 5.2 | 5.2 | 5.2 | |||

| Thermal conductivity | 25°C | W/(m・K) | 180 | 200 | 230 | |

| 300°C | 120 | 130 | 145 | |||

| Specific heat | 25°C | J/(㎏・K) | 720 | 720 | 720 | |

| Electrical | Dielectric constant | 1MHz | - | 8.5 | 8.5 | 8.5 |

| Dielectric loss factor | 1MHz | 10-3 | 0.3 | 0.3 | 0.3 | |

| Volume resistivity | 25°C | Ω・㎝ | >1014 | >1014 | >1013 | |

| Breakdown strength | DC | ㎸/㎜ | >15 | >15 | >15 | |

General Dimension

| Item | Unit | Type | ||

| AN-170 | AN-200 | AN-230 | ||

| Dimension | inch(max) | 5.5"×7.5" | 5.5"×7.5" | 5.0"×7.0" |

| Tolerance | ±1% NLT:±0.1㎜ | ±1% NLT:±0.1㎜ | ±1% NLT:±0.1㎜ | |

| Thickness | ㎜ | 0.25~1.5 | 0.25~1.5 | 0.25~1.0 |

| Tolerance | ±10% NLT:±0.04㎜ | ±10% NLT:±0.04㎜ | ±10% NLT:±0.04㎜ | |

| Through hole | ㎜ | Φ0.2~ | Φ0.2~ | Φ0.2~ |

| Tolerance | ±0.05㎜ | ±0.05㎜ | ±0.05㎜ | |

| Warpage | ㎜ | 0.002/㎜ | 0.002/㎜ | 0.002/㎜ |

Processing

-

Mechanical Processing

-

Polishing / Lapping

-

Metalization