Ceramic Substrates

Metallized / Multilayer Ceramic Substrates

Ultra High Purity SiC Components

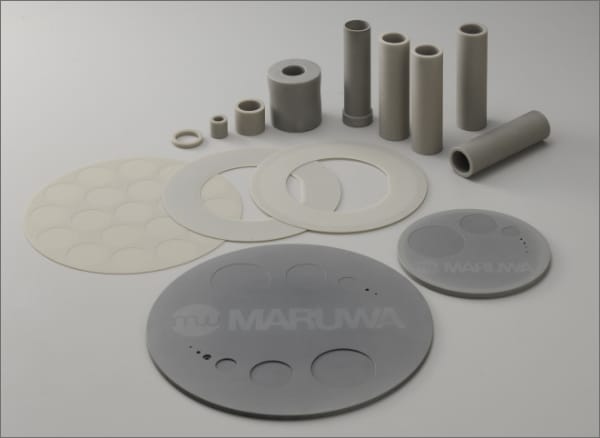

Pressed Ceramic Products

Semiconductor Product

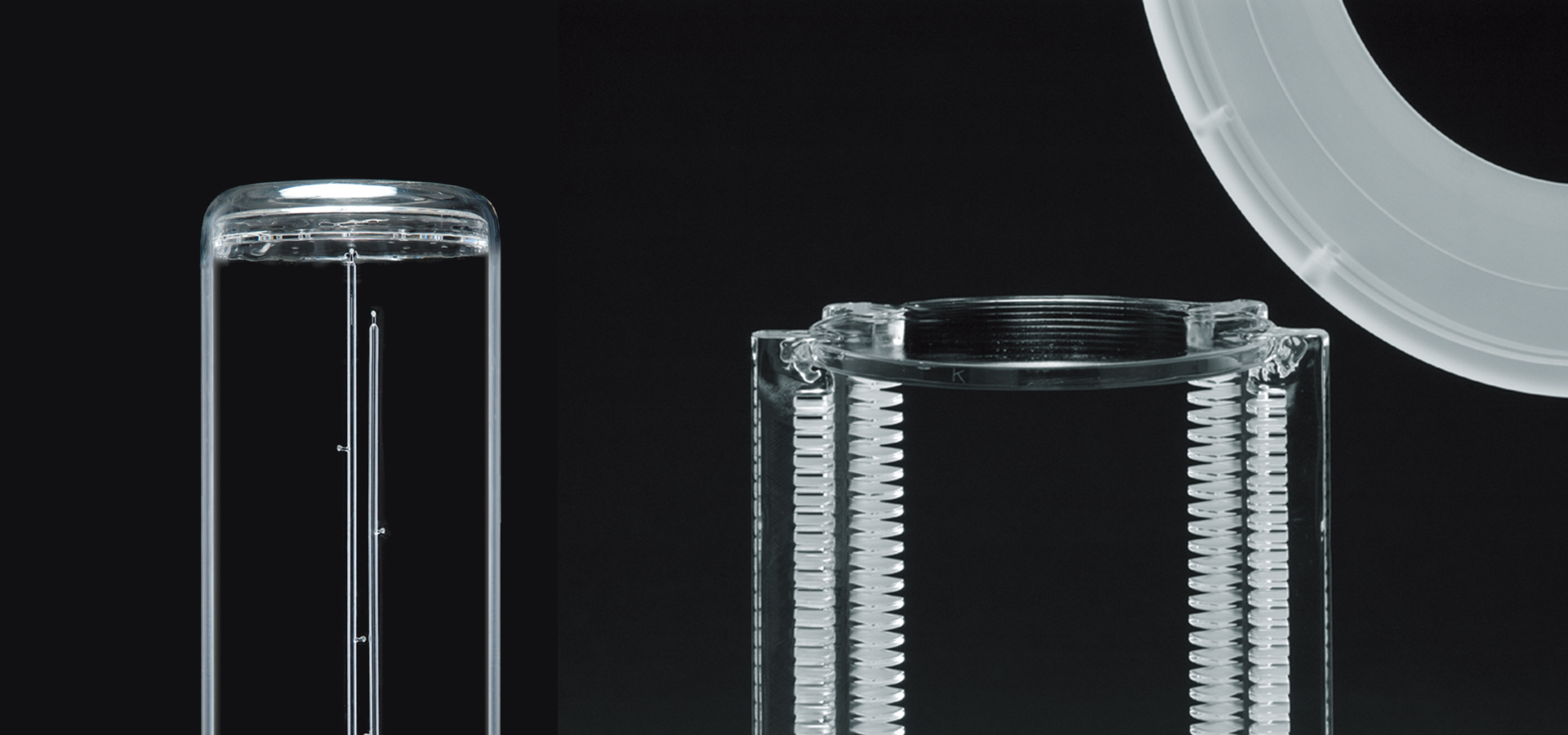

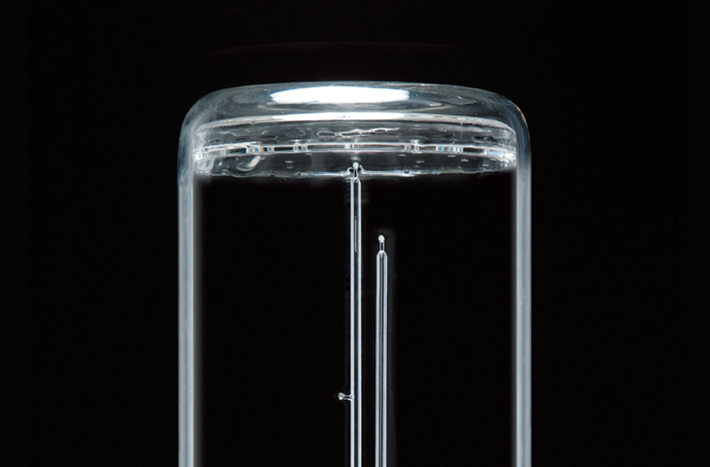

MARUWA's quartz glass products are manufactured with high-purity quartz materials which are chosen very carefully. Our strengths are in distinguished technologies and production systems that are under fully-controlled clean environment. We provide products based on customers' needs; quartz tube and quartz boat for manufacturing process (large-size available) of semiconductors, and for manufacturing process of next generation products (optical fiber / solar cell).

Large Size Products

Installed large-diameter lathe and machining process equipments for targeting to manufacture next generation applications; 18 inches (450mm). Established the manufacturing technologies for large-size products, such as furnace tube for 12 inches (300mm) wafers.

-

Large Diameter Lathes

-

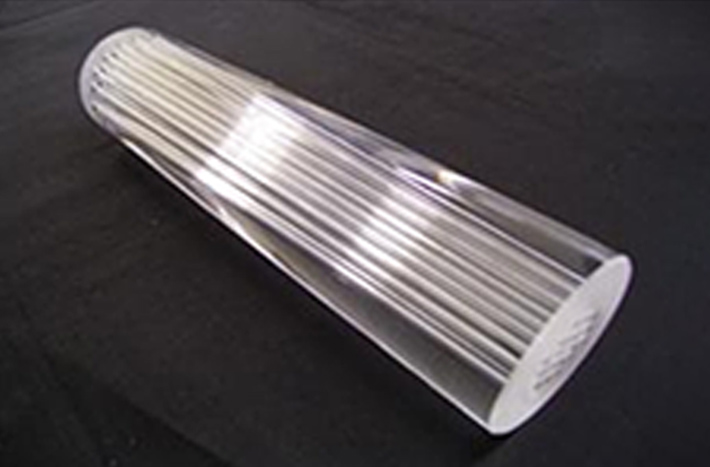

Micromachined Products

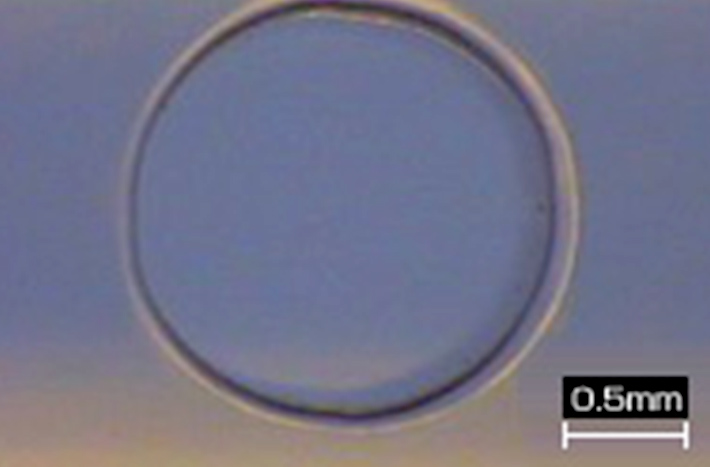

Established precision grinding process with the cutting-edge NC machining center, and precision micromachining technology (small hole boring process, etc.). We can also take curve cutting process with laser cutting machines (ex. Pinhole for gas tube)

-

Example of micromachining

-

Example of fine hole by laser

Integrated Production under the Clean Environment

All of the process after firing process are under clean environment in order to avoid contamination on the products. Especially, shipping inspection, final cleaning, vaccum packaging processes are done under extremely controlled clean environment which is below class 1000. Therefore, it is possible to dispatch the products without any contaminations.

Product Groups

For Semiconductor Industry

Available for all sorts of semiconductor manufacturing processes; diffusion CVD, washing, etching, etc.

Large size products, up to 12 inches (450mm), are available.

-

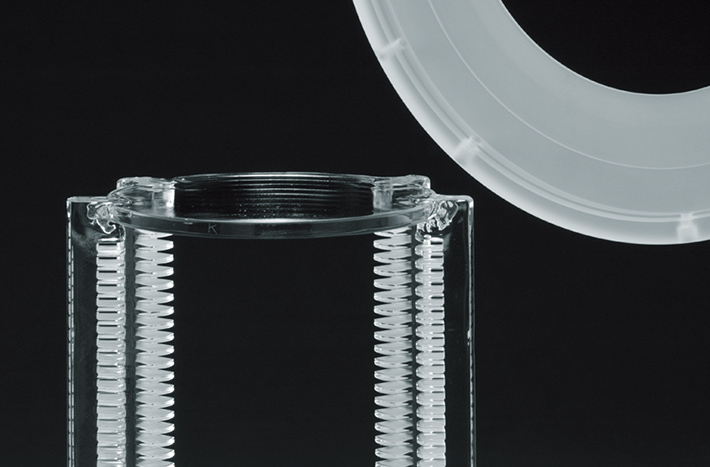

Tube Products

-

Process tube

-

Outer tube

-

Inner tube

-

-

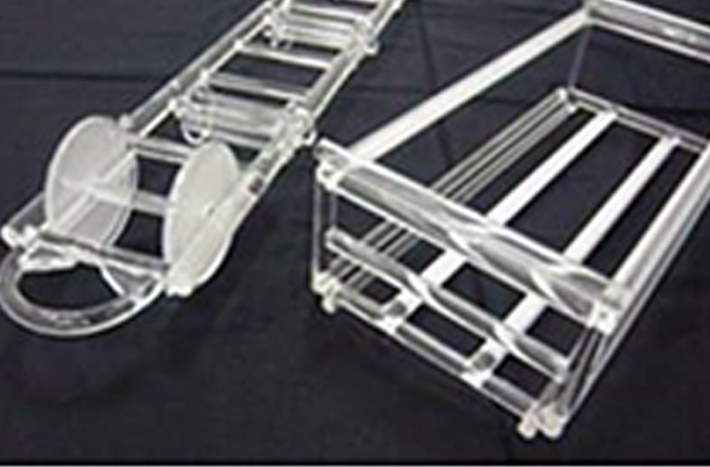

Process Jigs / Etcher Products

-

Quartz Boat

-

Other Jig

-

Chamber

-

Ring

-

-

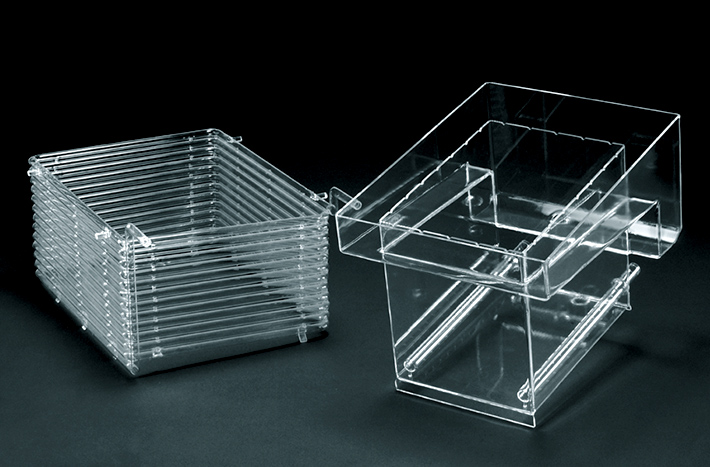

Washing Process Tools

-

Over Flow Bath

-

Carrier

-

Guide

-

-

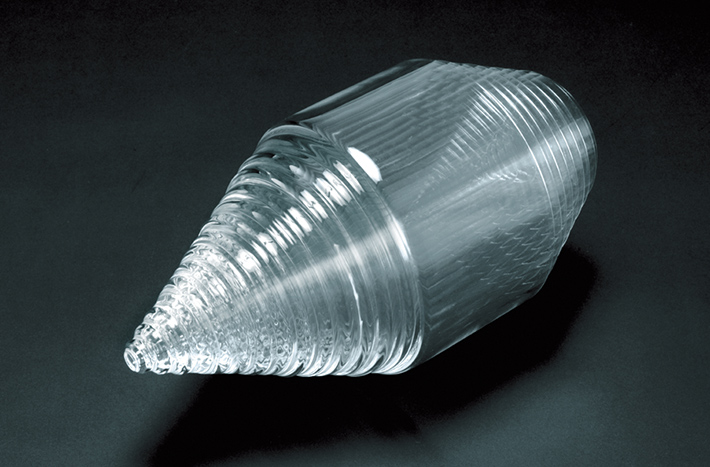

For Compound Semiconductor Industry

MO-Available for each process, such as MO-CVD

-

Tube type reactor

-

Box type reactor

-

Large Tray

-

-

For Optical Fiber Industry

Available for each process; ex. optical fiber base materials, burner, chamber, etc.

-

Quartz Furnace Tube

-

Quartz Multi-tube Burner

-

Optical Fiber Base Materials with Pinhole Process

-

Quartz Chamber

-

-

For Solar Cell Industry

Quartz Products for silicon wafers are also available.

-

Quartz Tube

-

Quartz Boat

-

Ultra High Purity Fine Ceramics SiC Components (PureBeta)

Introducing PureBeta, an ultra-pure, high-density SiC sintered material with excellent properties.

Aluminum Nitride (AlN) Components

With high thermal conductivity, high wear and corrosion resistance, Aluminum Nitride (AlN) is the most ideal material for the semiconductor and medical industries. Typical applications include: heaters, electrostatic chucks, susceptors, clamp rings, cover plates and MRI equipment. Based on a depth of material engineering and development, MARUWA offers a wide range of technical capabilities and dependable mass-production capacity to meet customer’s requirements in the most advanced fields of semiconductor and medical applications.

List of Products

Semiconductor manufacturing equipment (heaters, electrostatic chucks, susceptors, clamps rings, cover plates) and medical equipment